Co-Generation System

Based on our rich track records of Co-Generation System installations, we undertake furnishing proposals not only for new system installations but also proposals for the most economical ways of operation and maintenance of co-generation system supplied by others.

If necessity of cost reduction on co-generation system operation is in mind, please feel free to contact us.

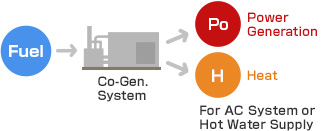

What is "Co-Generation System" ?

Co-Generation System is a combination of power generation by fuel combustion such as heavy oil or gas and efficient usage of heat generated at the same time for air-conditioning, hot water supply or steam supply. The system is quite effective for cost reduction, energy saving and environmental issues. For power generation system, engine or turbine is driven and heat from exhausted gas or from cooling water is recovered to effectively be used.

Purpose of System Introduction

- 1. Stable power supply and peak cut

- By installing Co-Generation System as distributed power source, it enables to secure power source even in the event of emergency, avoiding undesired production and opportunity loss. The stable plant operation and product supply maintains credibility from customers as well as stake holders like shareholders. Flexible own energy control is manageable in the event of unexpected restriction for power consumption required by public regulation or power company.

- 2. Counter measure for energy and power cost saving

- As consequent impact of suspension of nuclear power plants operation, power rate tends to be hiked. By cutting peak demand of electric power, an increase of expenses due to power rate hike is possible to be depressed. Furthermore the effective utilization of waste heat highly contributes to energy saving management.

Benefit of System Introduction

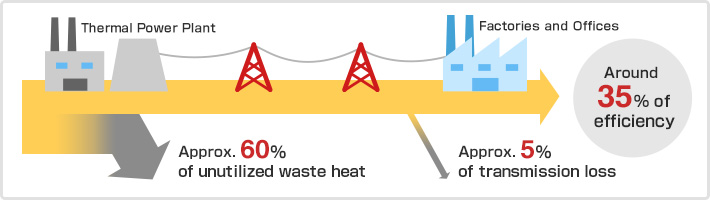

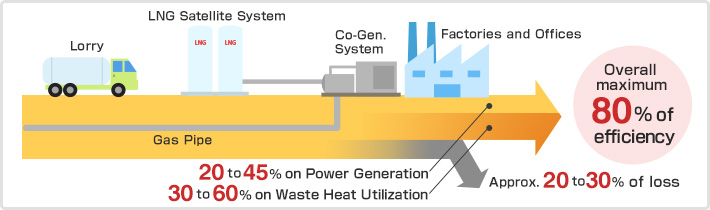

The greatest benefit is to reduce energy consumption cost. By exhausted heat usually disposed being recovered and utilized for air-conditioning, hot water supply or steam supply, the energy saving and CO2 reduction is achieved at factories or workshops. Though it may depend on operational conditions, energy efficiency becomes 70 to 80% in combination of power generation and heat recovery. (In our record, maximum 92% efficiency was achieved).

- Conventional Power Generation

- Co-Generation System

∗Note: The balance of energy efficiency is depending on equipment installed.

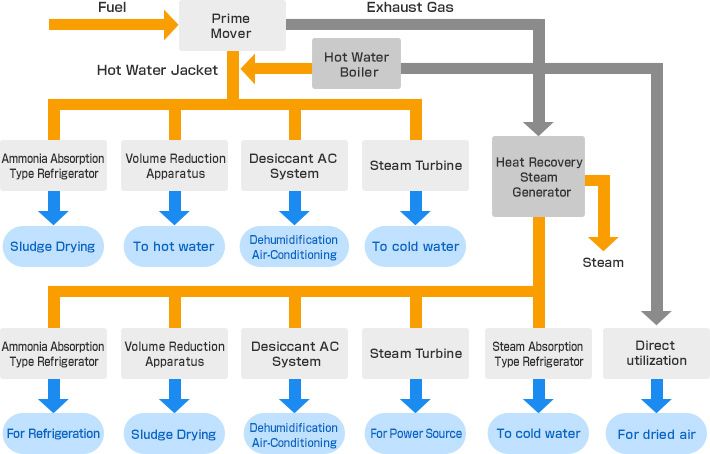

Destination of Waste Heat Utilization

In order to utilize the heat generated by prime movers, some specific equipment or facilities to effectively utilize the heat from exhausted gas or engine coolant are required.

Main Equipment

- 1. Heat Recovery Steam Generator

- When fuel is combusted in a prime mover as internal-combustion engine, exhaust gas is generated. Though the exhaust gas temperature may depend on the kind of prime mover or its rated power, steam is generated by the heat passing through boiler with temperature of 350 to 550 ℃. The generated steam can be directly utilized or may be forwarded to facilities that require heat.

- 2. Volume Reduction Apparatus

- Steam or waste heat from engine coolant is utilized with the volume reduction apparatus. The equipment reduces volume and weight of waste by evaporating water with the heat.

- 3. Heat Exchangers

- Heat exchanger is equipment that performs heat exchange by flowing through fluid. In the co-generation systems, the equipment is mainly employed for heat exchange of engine coolant.

- 4. Desiccant Air-Conditioning System

- Desiccant AC System consists of functions for dehumidification and heat recovery, which removes humid from ambient air with desiccant such as Silica Gel or Zeolite and regenerates comfortable air.

- 5. Hot Water Absorption Type Refrigerator, Steam Absorption Type Refrigerator, Ammonia Absorption Type Refrigerator.

- Absorption type refrigerator is equipment which generates cooling water from vaporization heat from engine coolant or steam out of HRSG (Heat Recovery Steam Generator).

- 6. Steam Turbine

- Steam turbine is equipment which generates electric power by running turbine with steam. It is recommended for a client who consume big volume of power and does not utilize much of steam.

- 7. Small Steam Turbine, Binary Power Generation System

- These are equipment to generate electric power utilizing excess steam or waste hot water that was used to be difficult to effectively utilize before.